Ceramic glass, also known as glass-ceramic or vitroceramic, is a special type of glass that has been processed to have properties of both glass and ceramics. It is created through controlled crystallization of certain glass compositions, resulting in a material with unique characteristics that make it suitable for a wide range of applications.

The production of ceramic glass involves a two-step process:

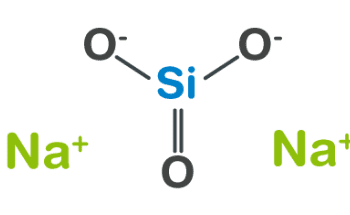

- Glass Formation: Initially, a glass is formed through conventional glassmaking techniques. The glass composition typically consists of a mixture of silica (sand), alumina, and other oxides.

- Controlled Crystallization: The glass is then subjected to a carefully controlled heat treatment process known as “nucleation and crystallization.” This process encourages the formation of fine crystals within the glass matrix. The size, distribution, and type of crystals formed can be precisely controlled to achieve specific properties.

Key characteristics and features of ceramic glass include:

- Thermal Resistance: Ceramic glass is highly resistant to thermal shock and extreme temperature changes. It can withstand rapid heating and cooling without cracking or breaking, making it suitable for applications where thermal durability is essential.

- Mechanical Strength: The presence of crystals in the glass matrix gives ceramic glass enhanced mechanical strength compared to conventional glass. It is less prone to chipping or breaking under normal conditions.

- Transparency: Ceramic glass is generally transparent or translucent, allowing light to pass through it. It is commonly used for glass-ceramic cooktops, fireplace doors, and architectural glazing, where transparency is desirable.

- Low Thermal Expansion: Ceramic glass exhibits low thermal expansion, which means it expands or contracts minimally with changes in temperature. This property contributes to its thermal shock resistance.

- Chemical Resistance: Ceramic glass is resistant to chemical corrosion and does not react with most chemicals. This property makes it suitable for use in laboratory equipment and certain industrial applications.

- Versatility: Ceramic glass can be molded into various shapes and sizes, making it suitable for a wide range of applications, including cookware, fireplace doors, cooking surfaces, and glass covers for electronic devices.

Applications of ceramic glass include:

- Cooktops and Stovetops: Glass-ceramic cooktops are widely used in modern kitchens for their thermal resistance and smooth, easy-to-clean surface.

- Fireplace Doors and Inserts: Ceramic glass is used in fireplace doors and inserts due to its ability to withstand high temperatures and provide a clear view of the flames.

- Laboratory Equipment: Glass-ceramic materials find applications in laboratory glassware, such as crucibles, dishes, and ceramic glass cookware used for sample preparation and analysis.

- Architectural Glazing: Ceramic glass is used in architectural glazing for windows, doors, and partitions, where its transparency and thermal properties are beneficial.

Ceramic glass combines the best properties of both glass and ceramics, making it a versatile material with a wide range of practical applications across various industries. Its unique combination of thermal resistance, mechanical strength, and transparency continues to make it a valuable choice for modern technologies and consumer products.